Wood is hygroscopic. This means that it will absorb water when the relative humidity increases and lose water when the relative humidity decreases. As wood absorbs moisture it swells and as it loses moisture it shrinks. This swelling and shrinking varies across the three main planes of the wood grain: tangential, radial and longitudinal. Knowing how grain orientation affects wood movement and orienting the grain on both parts of a joint to minimize the difference in movement between the parts is an essential part of creating a strong and lasting joint.

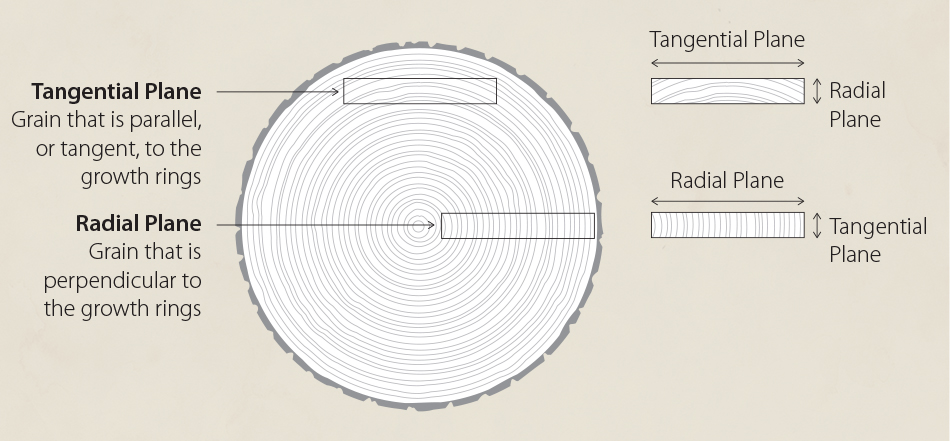

Tangential and radial grain can be seen in a cross-section of a log or board. The tangential plane is grain that is parallel, or tangent, to the growth rings. The radial plane is grain that is perpendicular to the growth rings and runs from the center of the log to its outside or “heart to bark.” Long grain is the grain we see on the face or sides of a board and runs vertically up a log or a board.

Although it varies by species, in general, tangential grain will swell and shrink twice as much as radial grain as shown in the illustration below. The cylinder on the left, turned from green wood, is perfectly round. As it dries it becomes oval in shape because of the difference in shrinkage between the radial and tangential planes as shown on the right.

Longitudinal grain has virtually no swelling or shrinking. In fact, the swelling or shrinking of longitudinal grain is so small you can effectively ignore it and assume that there is no wood movement along the length of a board.

So, how do we apply this knowledge when deciding how to orient the two parts of a joint. Let’s look at a joint with a turned rung tenon going into a mortise in a turned leg. The idea is to orient the parts so that, to the extent possible, the wood movement in both parts complement each other across all three planes. In the example below the tangential grain in both parts (A) are aligned so that, along the tangential plane, the parts will shrink and swell about the same amount (especially if both parts are the same wood species). Next align the radial grain in the rung (B) with long grain in the leg (B). Although the radial grain will shrink and swell and the long grain will not, given a choice between radial or tangential grain, radial grain is the better choice since its wood movement is about half that of the tangential grain. And for the same reason align the long grain in the rung (C) with the radial grain in the leg (C).

Unfortunately we cannot always align parts with their ideal grain orientation. In the illustration on the left, the relationship of the long grain in the rung and the radial grain in the leg is ideal. However in an actual chair there will be rungs going into the leg from two directions. The solution is to split the difference by rotating the leg so that its radial grain is at a 45° angle to the long grain in the rungs. This will make both rungs equally happy (or equally unhappy, depending on your point of view).

Working with grain orientation and aligning both parts of a joint is easy with turned parts because you can simply rotate the part to the correct orientation. However for parts that are not turned the job of grain orientation begins with milling to the correct grain orientation from rough boards. In my next post I’ll talk about grain orientation for the other parts of a chair—slats, rear legs, arms, and runners.

Related post: Grain Orientation and Wood Movement, Part 2